Amazing Clarity for Agricultural Water

Mar 2013, Brent Baiden, Orival Canadian Representative; Dr. Marcus N. Allhands, PE, VP Business Development Orival, Inc.

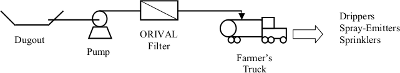

System overview.

Figure 1: ORIVAL ORG-040-LS Pilot Filter

Figure 2: ORIVAL ORG Cutaway

Location Northern Sunrise County is a picturesque Municipal District in Northern Alberta offering over 21,500 square kilometers (8300 square miles) of adventure and exploration in a pristine landscape. Located 485 kilometers (300 miles) north of Edmonton, Northern Sunrise County is a short drive south of Peace River. Farmer’s markets, museums, hunting, fishing, golfing, camping, early Native American re-enactments, the Harmon Valley Rodeo, many parks and a winter carnival make this a year-round vacation spot.

The Problem

Steady growth in population, industry and tourism has caused higher demands for potable water in Northern Sunrise County, exceeding the capacity of the two local water treatment plants. In 2004 the county decided to initiate a program to lower the demand on potable water for non-potable uses. One aspect of this program was to discourage the use of potable water by farmers for irrigation by providing farmers with a ready source of non-potable irrigation water. To this end, 150 micron manually cleaned strainer baskets were installed in two locations. Though not as clean as treated potable water, local producers supported the effort. The problem with the filtered water was that it was still not clean enough and using treated drinking water caused a suspected reaction between the chlorine in the water and the ag chemicals with deposits plugging the sprayer nozzle fine filter screens. To conserve water, irrigation systems in use today have micro-spray emitters close to the ground that spray a fine mist of water onto crops. This method increases irrigation efficiency by directing most of the water onto the ground right around the plants to cover the root zone and minimizes drift and evaporation losses. Because these micro-spray emitters have such a small orifice, the water must be free from all solid particles that could cause clogging. Some farmers may soon start using drip irrigation technology, which is more efficient than micro-spray emitters but is even more dependent upon high water quality. If the water provided to farmers by the county is not clean enough, the farmers will simply go back to using potable water for irrigation purposes increasing the strain on the public water supplies. Only quality filtration equipment can remove both heavy solids such as sand and lighter organics like algae, rendering non-potable water usable for irrigation purposes. A better filtration system was needed.

The Solution

Mr. Brent Schapansky, County Utilities Coordinator was called upon to lead the project. Storm water and spring runoff is collected in ponds and basins, called dugouts, throughout Northern Sunrise County. This water picks up sand, grit and wind-blown debris making it unfit for modern water-conserving irrigation systems. Mr. Schapansky contacted Orival, Inc. for an automatic self-cleaning filtration solution. A.R. Thomson Group, the Orival Western Canada representative, became involved right away providing design and service assistance to the county. An Orival ORG/A-040-LS Automatic Self-Cleaning Filter with a 50-micron weave-wire stainless steel screen was installed as a pilot filter to determine the feasibility of using automatic self-cleaning screen filters to treat the water from the dugouts to prevent clogging of farmers’ irrigation systems. Figure 1 shows the pilot filter after installation. Farmers simply pull up to a dugout with their tanker trucks and fill up with water to haul back to their fields for irrigation. The filtration system sits between the pump and truck assuring high water quality for the most stringent irrigation system.

“Water coming out of the Orival filter tested over the Alberta drinking water standard with no chemical treatment.”

Filter Operation

Water passes into the filter body at the bottom as shown in Figure 2 and then through the 50-micron cylindrical screen element from inside out. Suspended solids larger than 50 micron are retained on the screen surface and soon build up a layer called a filter cake. The openings between particles in this filter cake are smaller than 50 microns so the filter cake acts as a filter medium capturing smaller and smaller particles. When a differential pressure switch senses a sustained pressure drop of 7 psi across the filter, it signals the controller to initiate a rinse cycle. A rinse valve (1” on this filter model) opens the internal rinse chamber to atmosphere dropping the pressure in the chamber. Water wants to move from the high pressure-filtering chamber to the rinse chamber but can only do so by passing into nozzles on the dirt collector and out the hydraulic motor in the rinse chamber. This water movement causes the hydraulic motor to rotate the dirt collector. The nozzle openings are so close to the screen element that water rushes backwards through the screen (from clean side to dirty side) in a very small area at high velocity pulling the filter cake off the screen, into the nozzles, through the dirt collector, into the rinse chamber and out the rinse valve to a convenient drain. A piston on top the filter is normally pressurized by water pressure holding the dirt collector down to its lowest position. During the rinse cycle this pressure is bled off allowing the dirt collector to be slowly pushed upward by pressure in the filter chamber. The combination of rotation and upward linear movement causes the nozzles to pass every square inch of screen area assuring a clean screen. After about 12 seconds the cleaning cycle is complete and the rinse valve closes, the dirt collector stops rotating and the piston is re-pressurized to place the dirt collector back into its lower starting position. While all this is happening, the filter continues to supply clean filtered water downstream to the truck without interruption.

The Results

Mr. Brent Schapansky continues hands-on involvement with project operations. Brent takes water samples to conduct water quality analyses to assure farmers of trouble-free water. Based on these test results he said; “Our water coming out of the [ORIVAL] filter tested at 1.1 NTU which is just over the Alberta drinking water standard by 0.1 NTU with no chemical treatment.” Local producers are thrilled with water quality and even with having to manually trigger filter cleanings on the pilot unit, they would not go back to the old system. The results of this pilot test have been so convincing that a second ORIVAL filter was purchased and set up as a fully automatic self-cleaning filtration system requiring no operator intervention whatsoever and the pilot unit will be incorporated into the local treated water reservoir building with a new submersible pump that has sufficient output to make the unit fully automatic as well. Supply at the pilot location is two dug-outs formerly feeding the small drinking water plant. A heated building and large supply means this site could remain open year round for industrial and fire fighting use. Locations like that of our second Orival unit, a rural dug-out will be seasonal only. More ORIVAL automatic filters are to be purchased as the program expands. The county is considering a by-law that will require all agricultural water come from filtered dugouts—a great testimony to a technology that meets a real need and a filter company that is dedicated to finding real solutions.