Filtration System Expenditure Results in Payback Measured in Days

Apr 2007

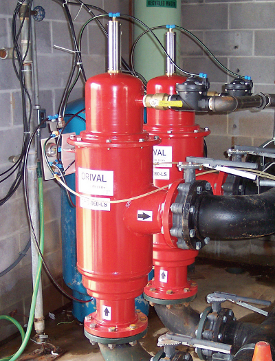

Two ORIVAL self-cleaning filters protect heat exchangers and vital instruments at the Philips Lighting Plant.

The Philips Lighting Plant in Danville, Kentucky

This manufacturer of household light bulbs experienced a real savings of $120,000 per year on a capital investment of $11,000 resulting in full payback in just 33 days.

It is very likely that every light bulb in your home or office came from the Philips Lighting plant in Danville, Kentucky. Nearly 10% of all the glass bulbs used to make incandescent light bulbs in the world are manufactured at this one location. In addition to these bulbs they make borosilicate hard glass for spotlight lenses and reflectors, and lead glass parts used in the manufacture of fluorescent tubes. Sand from one particular Tennessee mine is the main raw ingredient at this facility. Furnaces must reach temperatures in excess of 4000°F to melt the sand. Other additives such as sodium oxide, dolomitic limestone, lead and boron are added to this molten silica to produce the three specific types of glass used at this location.

“I couldn't believe that the filters were an in-stock item,” stated Mr. Broderick. “The vice president of Orival personally inspected the installation making a few efficiency adjustments to the controls. Now that's service.”

Glass plants use enormous amounts of water in their processes. This facility had tried recycling water in the past but ran into great difficulties. Heat exchangers would plug, cooling jackets would clog with debris and instruments used to detect the level of molten glass in furnaces would overheat when cooling water lines choked off. Production decreased, wastage increased and costly labor ran rampant. The expedient answer was to use potable water passing through the facility just one time then release to the environment through a permitted discharge. However, when this route was taken, purchased water consumption immediately doubled. Nearly a quarter of a million dollars a year was being spent on water alone. Resident engineers began focusing on the problem. After evaluating a number of alternatives, Tom Broderick, Maintenance Manager for Philips Lighting decided to install automatic self-cleaning screen filters in the pump house to remove sediments and suspended solids from the detention pond near their offsite discharge. This filtered recycle water was then sent back to the plant at flow rates varying from 800 to 1800 gpm for use in cooling vacuum pumps and other on-site uses. Because the two vertical turbine pumps took up so much space in the pump house and forklift access to periodically pull these pumps was necessary, most style filters could not fit into the available space. Mr. Broderick chose two ORIVAL Model ORG-060-LS automatic filters for the job since they were vertical in orientation and used so little flow for the self-cleaning process.

“I couldn't believe that the filters were an in-stock item,” stated Mr. Broderick. “The vice president of Orival personally inspected the installation making a few efficiency adjustments to the controls. Now that's service” he added. Broderick went on to say “Our water bill has decreased by $10,000 per month since installing the Orival filters. Commercial laboratory analyses have shown TSS in the filtered water to be just as low as in our available potable water supply.” John Wynd, Engineer-Fellow, Glass Operations says he is ready to install filters in another application to cut municipal water consumption even more. The bottom line: low capital cost, extremely fast payback and large yearly savings.