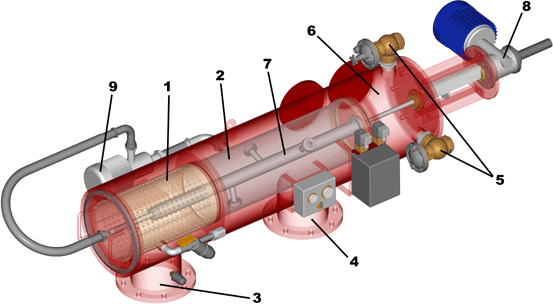

The unit consists of two stages of filtration, a coarse pre-filter 1 and a stainless steel fine screen 2

Dirty water enters the inlet 3, passes through the coarse screen and into the center of the fine screen. The water then passes through the fine screen from the inside out and exits the outlet 4.

The unwanted solids accumulate on the inner surface of the fine screen, creating a pressure differential. Once the pressure drop reaches a preset level, a rinse cycle is activated by the factory supplied control system by opening the rinse valve(s) 5 to an atmospheric drain.

As a result, pressure drops in the backwash chamber 6 and dirt collector assembly 7. The pressure drop creates a backflush stream, which sucks the dirt off the screen, similar to a vacuum cleaner. The backwash water is carried through the collector and ejected out of the holes in the base of the collector.

At the same time, the drive assembly 8 controls the movement of the collector assembly, ensuring that the collector nozzles sweep the entire screen area in a helical fashion, and returning the collector to its original position in preparation for the next cycle.

The filter is also equipped with a booster pump 9, which creates a high pressure water jet, directed at the inside surface of the screen, to assist in removal of sticky or otherwise difficult to remove particulate. The pump is controlled by the factory supplied control system and is only activated when necessary, conserving energy usage.