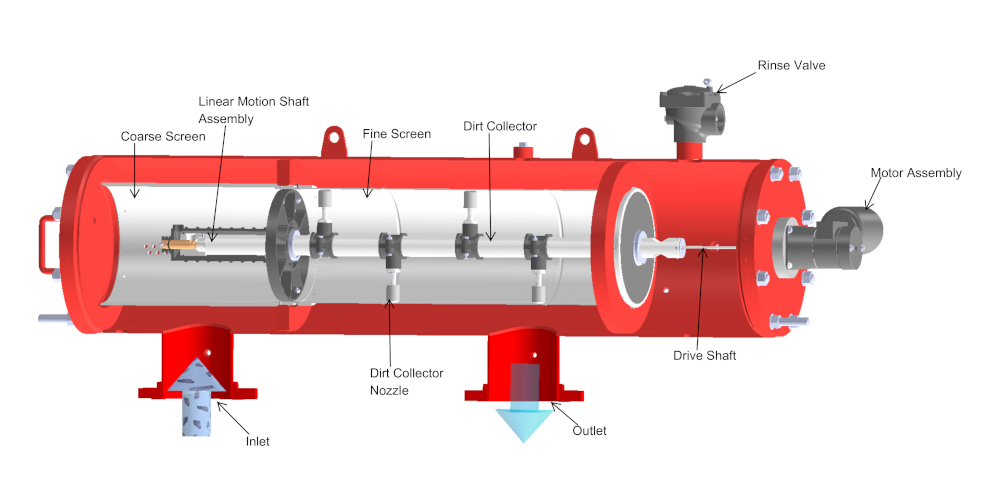

The unit consists of two stages of filtration, a coarse screen and a fine screen.

Dirty water enters the inlet, passes through the coarse screen outside-in, and enters the inside of the fine screen. The water then passes through the fine screen from the inside out and exits the outlet.

Unwanted solids accumulate on the inner surface of the fine screen, making it harder for water to pass through the fine screen and creating a pressure differential between the inlet and the outlet. Once the pressure differential reaches a preset level, the factory-supplied control system activates a rinse cycle by opening the rinse valve and starting the motor.

When the rinse valve opens to atmosphere, pressure drops in the rinse chamber. The dirt collector is hollow and connects the rinse chamber and the fine screen chamber, so pressure drops inside the dirt collector and its nozzles as well. The pressure drop causes the nozzles to work like vacuum cleaners, sucking in nearby particles. The nozzles are self-adjusting, allowing the nozzle openings to touch the surface of the fine screen. The water rushes into the nozzles at over 50 feet/second, carrying with it any material stuck on the fine screen. The intense energy can suck off even the stickiest particles.

Meanwhile, the dirt collector is slowly rotating and moving linearly. The drive shaft rotates the dirt collector, while the linear motion shaft moves it linearly. Both are controlled by the motor, on the back of the filter. Together, they ensure that the dirt collector nozzles pass over each part of the screen at least twice during the 45-second rinse cycle.