Protecting Artifacts at The Jewish Museum

Feb 2012, Dr. Marcus N. Allhands, PE, VP Business Development Orival, Inc.

The Jewish Museum at 1109 Fifth Avenue, Manhattan, NYC.

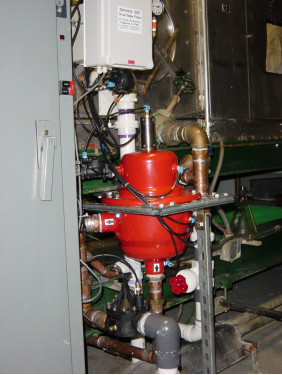

ORIVAL ORG-020-LE Automatic Filter at The Jewish Museum.

Thousands upon thousands of people visit 1109 Fifth Avenue in Manhattan each year. This is the location of The Jewish Museum, one of the largest of its kind in the world. For over 100 years this museum has displayed past and present Jewish culture, both secular and religious, to the world. Special care must be taken in protecting over 26,000 paintings, sculptures, works on paper, photographs, ethnographic material, archaeological artifacts, numismatics, ceremonial objects and broadcast media materials. This care begins with proper environmental conditions that rely on a dependable HVAC system.

A reliable, yet economical, means of removing suspended solids from the twin cooling towers was sought in the summer of 2010 to protect heat exchangers in the 150 ton chiller system that maintains the museum's temperature and humidity to precise set-points. The selected equipment was an ORG-020-LE Automatic Self-Cleaning Screen Filter from ORIVAL, Inc. The filter was set up as a side-stream system with about 20% of the full flow passing through the filter to reduce total suspended solids to a level that protects the heat exchangers from experiencing deposit buildup on heat transfer surfaces that would impact the efficiency of the HVAC system. As solids encounter the stainless steel weave-wire screen element inside the filter, all particles larger than the 100 micron openings are immediately blocked from passing. As these particles accumulate, a filter cake (layer of particles) develops. The pore spaces between these 100+ micron particles is smaller than 100 microns so this filter cake becomes a screening element of its own capturing smaller and smaller particles well below the 100 micron rating of the filter screen. As the filter cake thickens, a pressure drop develops across the screen element until a 7 psi threshold is met. At this point a differential pressure switch makes contact and sends a signal to the filter controller to initiate a rinse cycle to automatically clean the filter cake off the screen. Nozzles open to atmospheric pressure move across every square inch of screen surface vacuuming solids off the screen and discharging them outside the filter to a drain. The entire cleaning process takes 8-10 seconds. This procedure occurs whenever a 7 psi pressure drop is measured across the screen element. A timer built into the controller can also be used to initiate a rinse cycle with the elapse of a pre-set time interval.

“Inspection of the cooling tower basins after three months of filtration showed a noticeable improvement in tower cleanliness.”

Nick Silenko is an engineer for The Jewish Museum and project leader for the filter installation. He states: “Prior to the installation of the filtration system the cooling tower basins had to be manually cleaned at least every six months. Inspection of the cooling tower basins after three months of filtration showed a noticeable improvement in tower cleanliness.” At its installation, the filter experienced rinse cycles every 3-4 hours. The rate of solids accumulation on the screen began to decrease over time as the filter removed more and more solids from the system. A loosely defined “steady state” condition now exists where rinse cycles are every 24 to 36 hours. Heat exchangers are now maintained at high efficiency levels providing a reliable HVAC system to precisely control environmental conditions in the museum. Tens of thousands of artifacts are protected by a small red filter from ORIVAL.

Mr. Silenko says he is looking forward to the future installation of an ORIVAL ORG-040-LE automatic filter with a 5 micron screen on the incoming municipal drinking water to the museum to remove fine sand, pipe scale and grit.