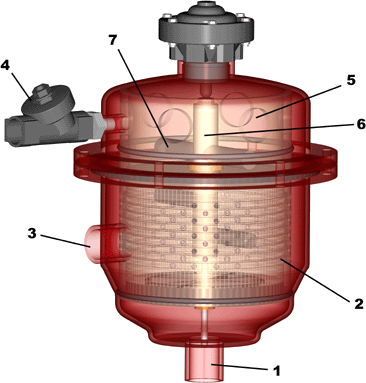

Dirty water enters the inlet 1, where it enters the center of the fine screen 2. The water then passes through the fine screen from the inside out and exits the outlet 3.

The unwanted solids accumulate on the inner surface of the fine screen, creating a pressure differential. Once the pressure drop reaches a preset level, a rinse cycle is activated by the factory supplied control system by opening the rinse valve 4 to an atmospheric drain.

As a result, pressure drops in the hydraulic motor chamber 5 and dirt collector assembly 6. The pressure drop creates a backflush stream, which sucks the dirt off the screen, similar to a vacuum cleaner. The backwash water is carried through the collector and ejected out of the holes in the hydraulic motor 7.

The water being ejected out of the hydraulic motor causes the collector to rotate, similar to a sprinkler. In addition, the pressure drop in the hydraulic motor chamber forces the collector assembly to move upward. This combination of movements ensures that the entire screen area is cleaned each cycle.